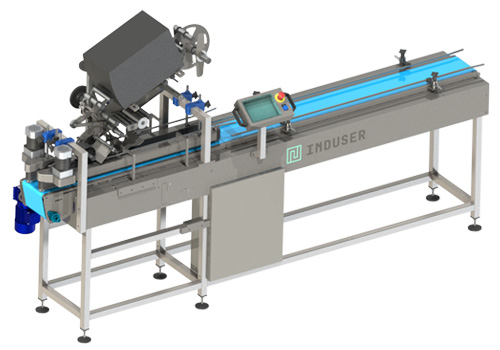

It labels packages in different formats (bags, glasses, trays), through a robust stainless-steel chassis.

Like other Induser solutions, the labeler is tailored to customer needs.

DOWNLOAD DATASHEET

Dispenses self-adhesive labels.

Reaching a speed of 25m/min.

Adjustable horizontal, vertical, and lower working position.

Communication with printer with the possibility of remote management.

Servo-controlled spool holder head.

Our machines are made of stainless steel and materials with the highest performance. This facilitates its regular cleaning and with it, its durability and profitability.

1) Crate pallet feeder.

A feeding table serves as an entrance to the crate pallet, which is served folded and in stacks. Through a horizontal movement system, it positions the platform so that each stack faces the entrance of the unfolding machine, while another push system introduces each stack.

2) Crate unfolder.

The crates enter the conveyor belt folded at one end and come out unfolded one by one at the other. The crates are later unstack by an incorporated system in the conveyor belt.

From 800 to 500 boxes per hour.

It works with boxes of 600x400 and 300x200cms.

Adjustable horizontal and vertical working position.

File transfer via USB port.

Servo controled axis system.

Our machines are made of stainless steel and materials with the highest performance. This facilitates their regular cleaning and with it, their durability and profitability.

Its objective is to reject all those products that do not meet the pre-established weight specifications. Induser's weight control increases the quality of the finished product and balances our clients' investment.

Our solution has a conveyor belt that introduces, weighs, and delivers the packages, equipped with a three-phase motor with IP-65 protection.

DOWNLOAD DATASHEET

Ensures weight of finished product.

Automatically memorizes the dimensions, speeds and weights of the product to be controlled.

Functionality to save and recover backup copies.

Height adjustment +/- 50 mm.

Through a servo-controlled coil-holder head.

Our machines are made of stainless steel and materials with the highest performance. This facilitates their regular cleaning and with it, their durability and profitability.

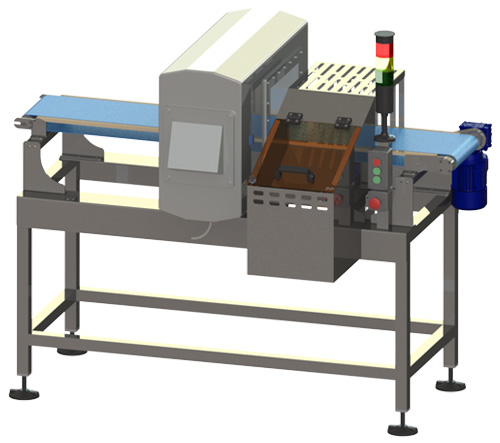

This solution is integrated into the complete packaging line to identify the presence of metallic contamination in the products, guaranteeing that they are eliminated from the production line and that they do not reach the consumer.

Like other solutions, the metal detector is automated to achieve optimization, removing any contaminated container, stopping the line, and alerting the operator for its detection.

DOWNLOAD DATASHEET

Optimal sensitivity to magnetic and non-magnetic metals.

Automation in the identification of contaminating materials in the container.

Intuitive and simple. Automatic configuration with 200 product memories.

File transfer via USB port.

IP 54 protection.

Our machines are made of stainless steel and materials with the highest performance. This facilitates their regular cleaning and with it, their durability and profitability.

Through a canvas conveyor, this solution allows container flaps to be closed with a pressure labeling system on the tray. The tray is a model with a high flap and small side clefts that allow the flap to fold and close against itself.

The casing machine has two side straps and longitudinal rails for folding the flaps with manual width and height adjustment. This sets the optimal width and height for each tray format.

ADVANTAGES

Ideal for sustainable packaging.

Close the tray using the same label, reducing costs for additional cases.

Valid for various formats with numerical regulations.

It is integrated into the automatic production line.

Optional printer with communication via ethernet with the server.

Our machines are made of stainless steel and materials with the highest performance. This facilitates their regular cleaning and with it, their durability and profitability.

We are certified by International Quality and Environment Care Organizations.