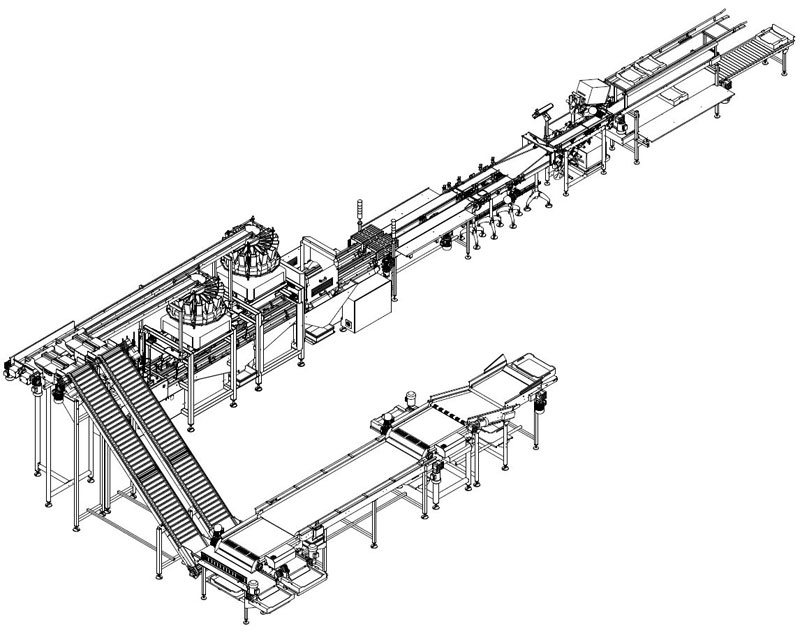

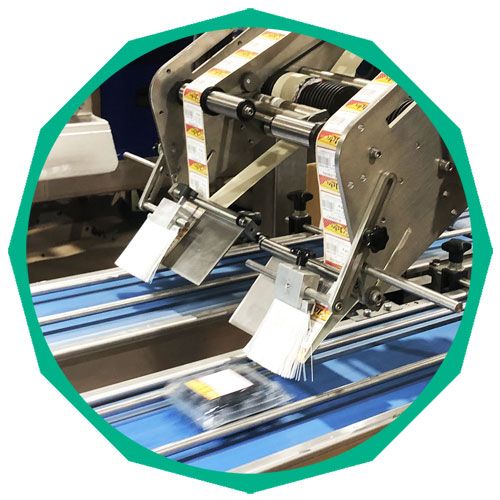

1.

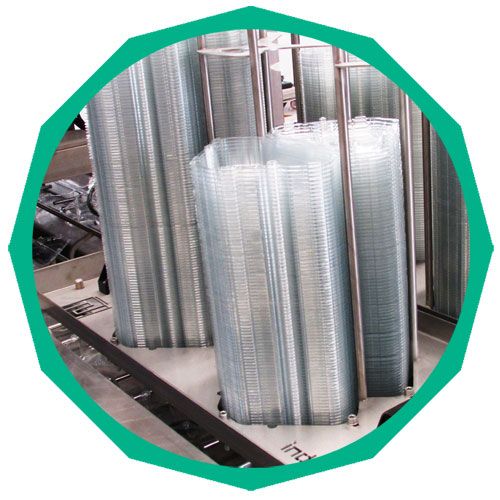

Nuts

Are packed quickly and efficiently, regardless of variety or format. More than fast, our multi-head weighers weigh the product with a margin of only +/-1g.

DOWNLOAD DATASHEET

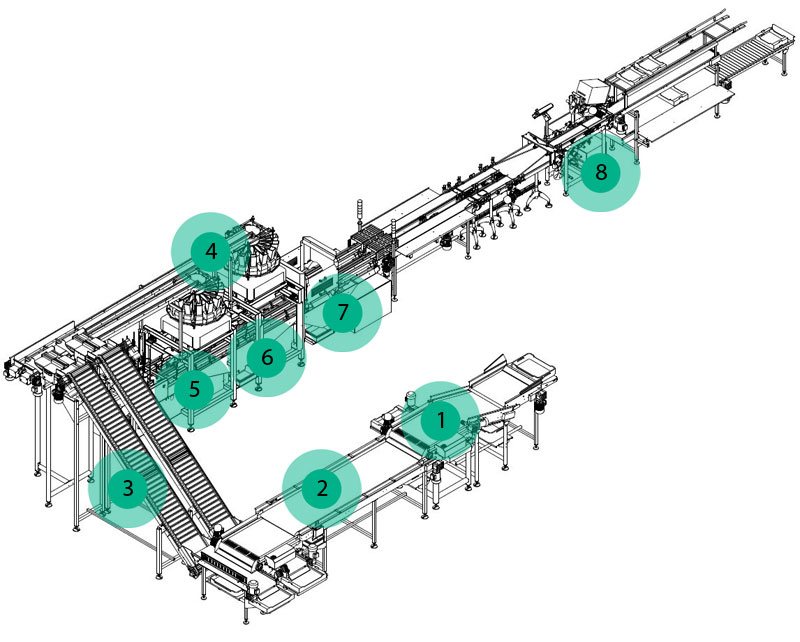

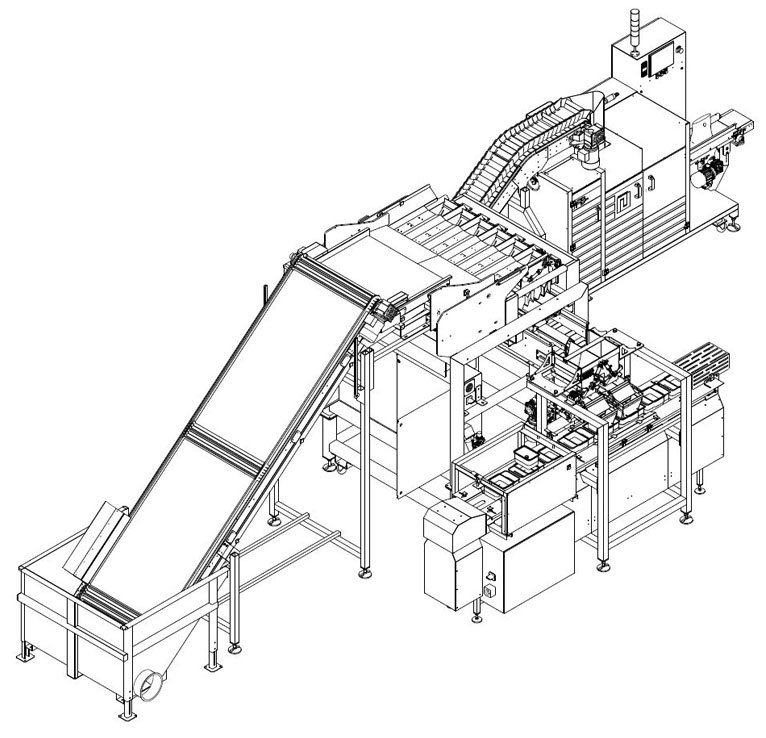

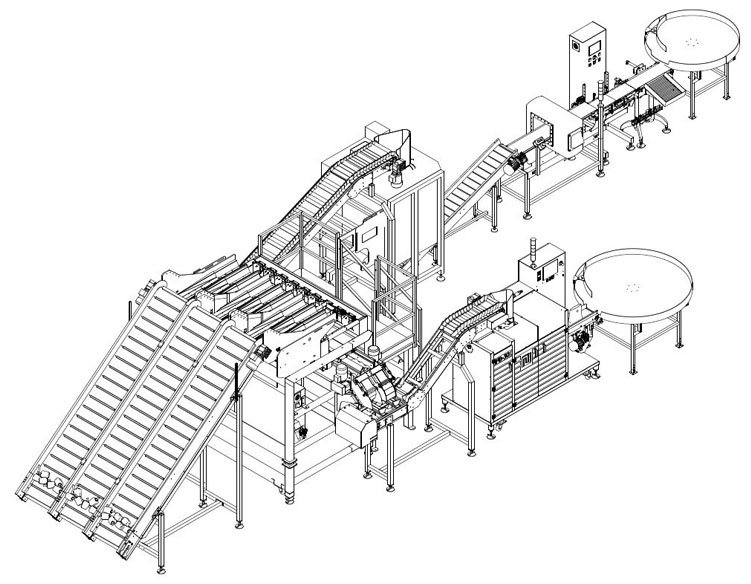

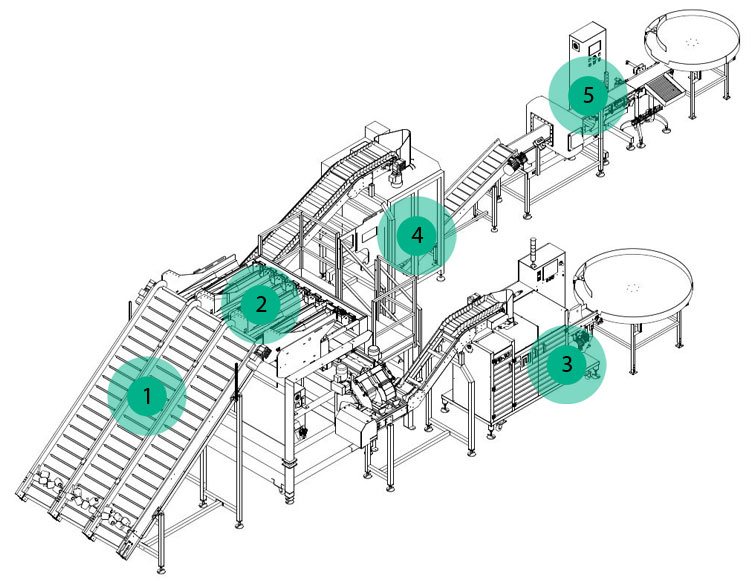

2.

Lechuga y IV Gama

The lettuce journey through the complete packaging line usually begins in a circular weigher and ends in a horizontal flow pack bagger.

Depending on the product, other packaging solutions can be used such as the FB30 or the vertical flow pack.

DOWNLOAD DATASHEET

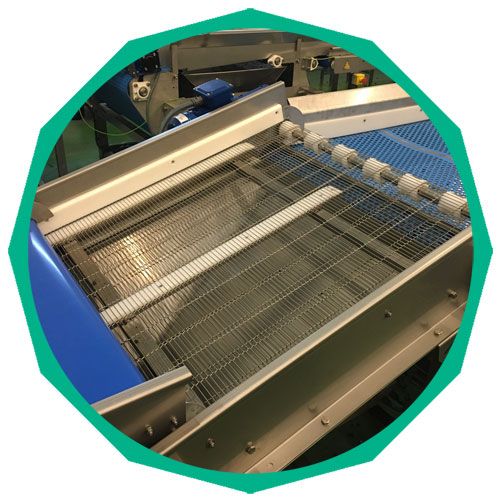

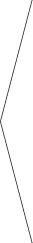

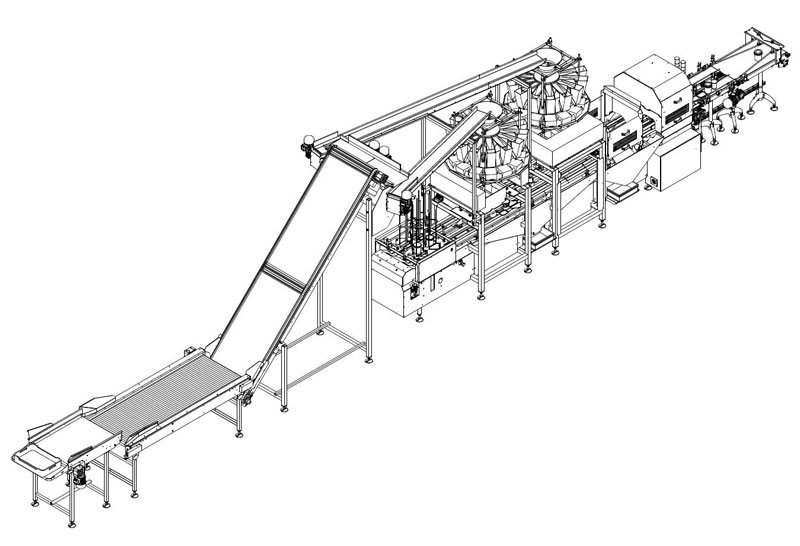

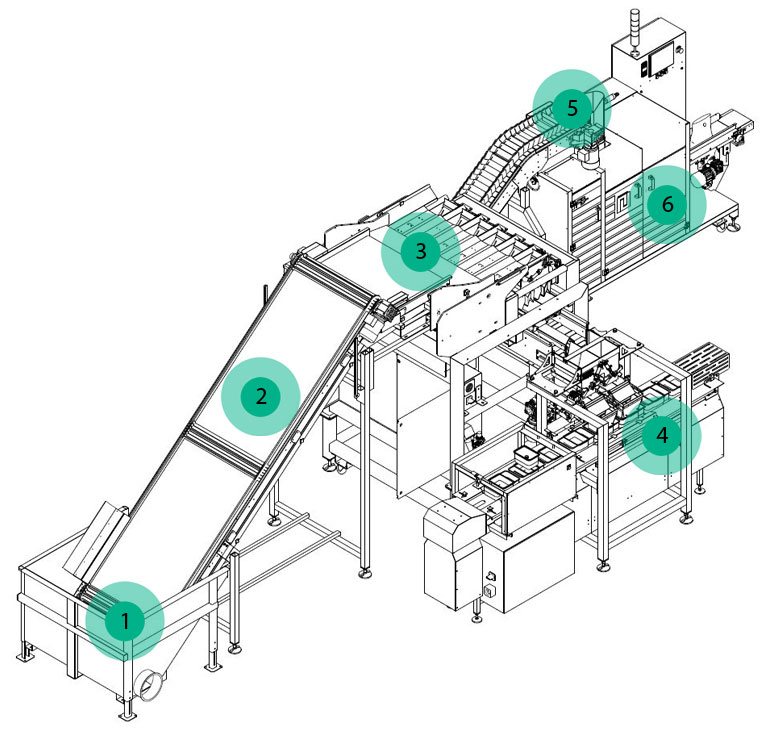

3.

Gominolas

We have designed complete packaging lines to bag jelly candies. The journey starts in a 12-head circular weigher with 1L hoppers and ends in a horizontal flow pack bagger.

DOWNLOAD DATASHEET

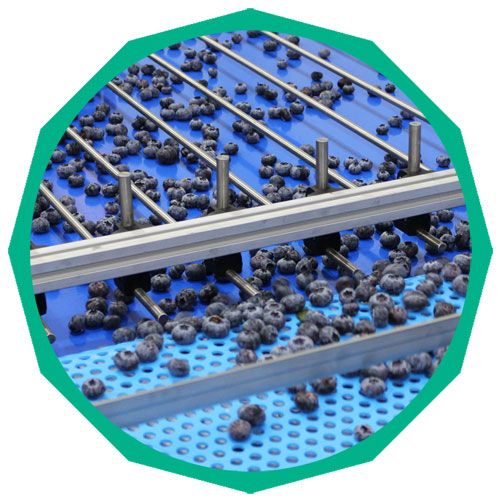

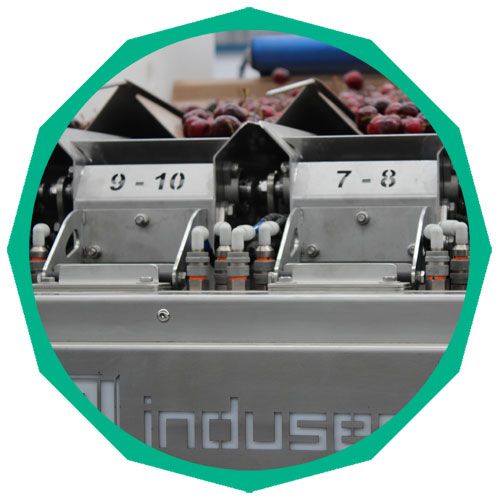

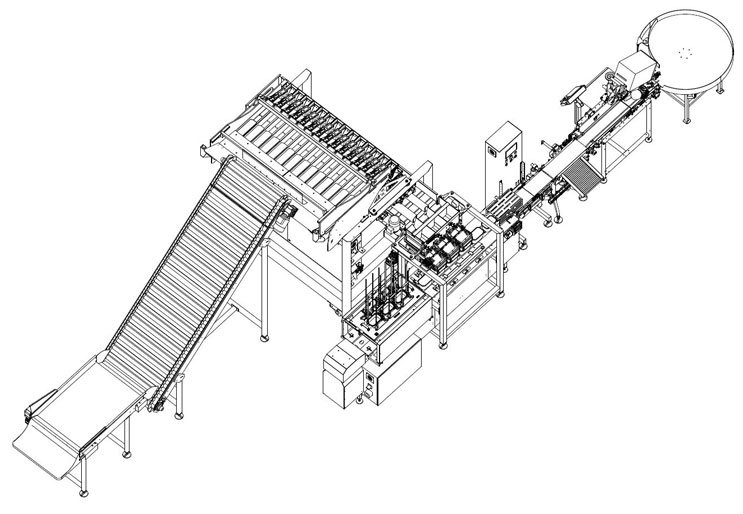

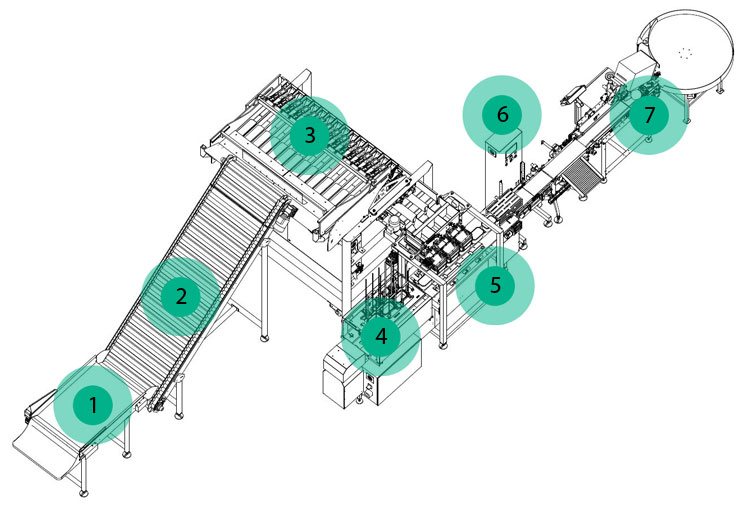

4.

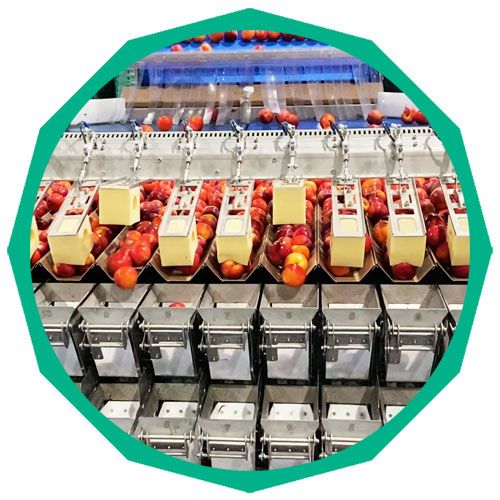

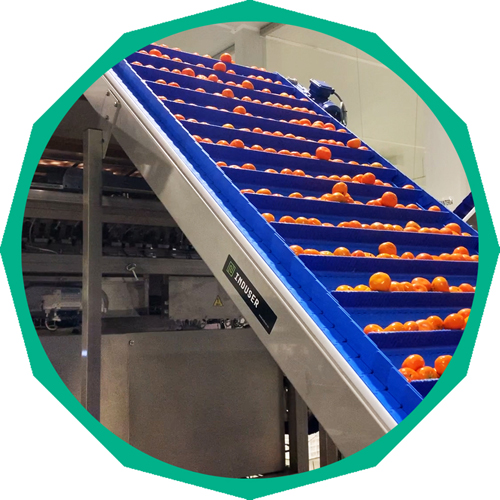

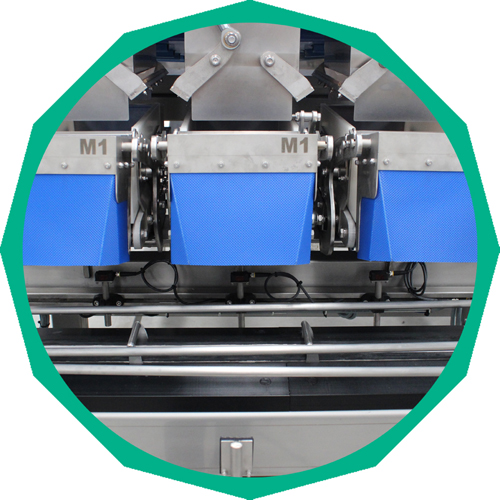

Kiwis / Avocados

Being multi-product is one of our strenghts. Both kiwis and avocados can be packed by an automated line that integrates the following machines: treatment and handling area, product elevator, associative linear weigher with 12-18 heads and a product packaging machine on a chain trolley.

DOWNLOAD DATASHEET