We help professionals in the fruit and vegetable sector by offering engineering solutions to make every gram of your production have value.

May 18th, 2023

Engineering Solutions

What is associative weigher for?

If you are a fruit and vegetable producer who is looking to automate your packaging process, optimize your production and make every gram count, pay attention to what we have to say about associative weighing.

Many of the small, medium, and large producers still resort to manual processes to package their products. This involves a team of people filling, weighing, and checking each container on an analogue scale. A slow and repetitive process that can be supported by technology and automation processes to achieve better performance, the optimization of the different resources, and the guarantee that the product will arrive fresh at the point of sale to comply with the commercial commitments agreed between the producer and the market.

This is where the functionality of the associative weighers comes into value! One of the first machines to be integrated into the packaging lines that we design and manufacture at INDUSER.

1 | Form follows function.

Associative weighers are machines that can have different shapes: circular, linear, horizontal. The shape follows the product to be packaged in each one of these. If it is blueberries, the most common is that a circular weigher is needed; in the case of apricots or peaches, it is common to use a linear weigher; it is elongated shapes such as zucchini or cucumber, the logical is to go for horizontal weighers.

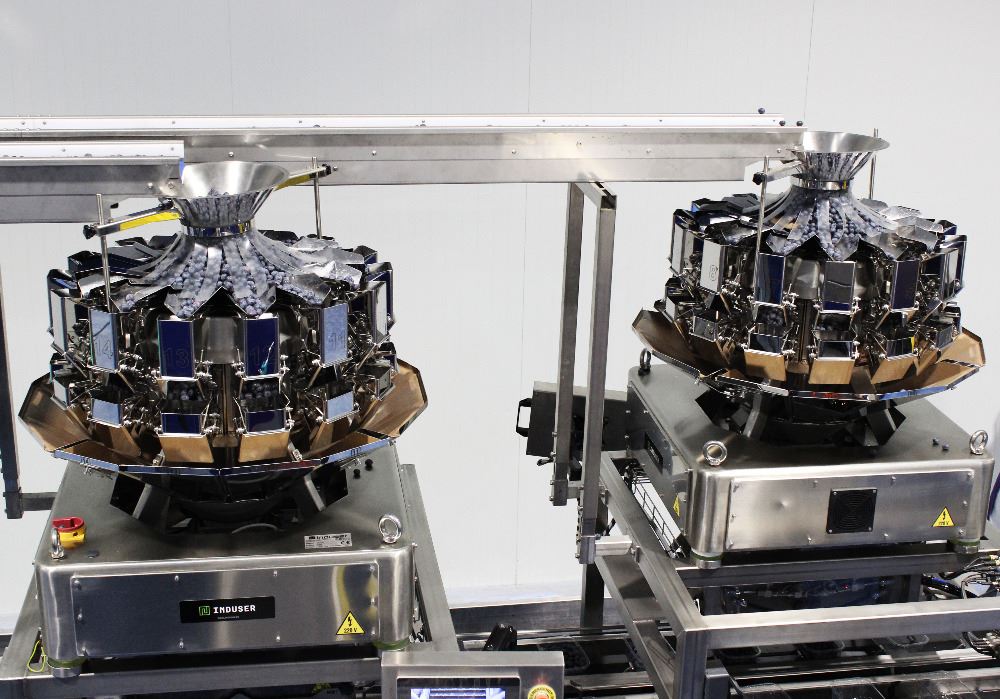

Circular Associative Weigher with 14 multiheads for Blueberries.

2| Appropriate product feeding and the use of vibrator to dose.

The basic principle for the proper functioning of an associative weigher is in the feeding of the product. Once the products are inside the weigher, a series of vibrators gradually dose them to feed the hoppers.

Lineal Associative Weigher with 14 multiheads for cherries.

3| The association of weights between different heads.

This is where technology does the math. If from the configuration software, it is established that each container must have a target weight of 500 grams, it is the machine that makes the sum between the different heads, until it checks that 500 grams per container is reached. The competitive advantage is that the association or combination of weight is possible because the heads work simultaneously.

Horizontal Packaging Line with 24 multiheads for Cucumber.

Why INDUSER associative weigher?

We would suggest that you leave the entire project in our hands. From the food to the machines that are integrated at the end of the line to guarantee the quality in each package.

But if this is not possible, what is relevant is that you consider that at INDUSER we adapt to the needs of each client, and that our objective is to achieve the production objectives that you have proposed.

To see the technical data sheets of INDUSER’s associative weighers, click on the machine that interest you the most: