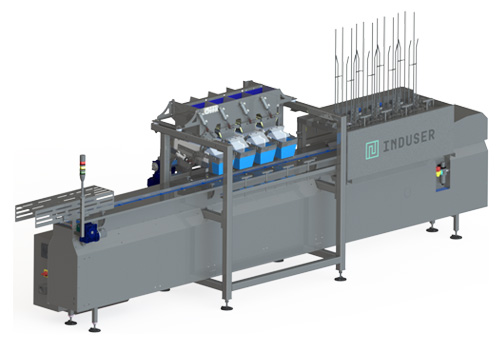

Its modular design allows you to choose the number of weighing heads (4, 8, 12, or 16) depending on your production targets, making it an adaptable option for evolving operations.

Whether you're handling soft fruit like blueberries or cherry tomatoes, the PGF ensures accurate weights, minimal product loss, and a smooth transition between formats – all while maintaining the delicate nature of fresh produce

We achieve the target weight of each tray through these two channels located on the vibrating trays that distribute the product to the filling and weighing hoppers.

The machine's design has been conceived to minimize product fall, ensuring gentle handling.

The machine's cadence adapts according to the number of heads, which can be 4, 8, 12, and 16.

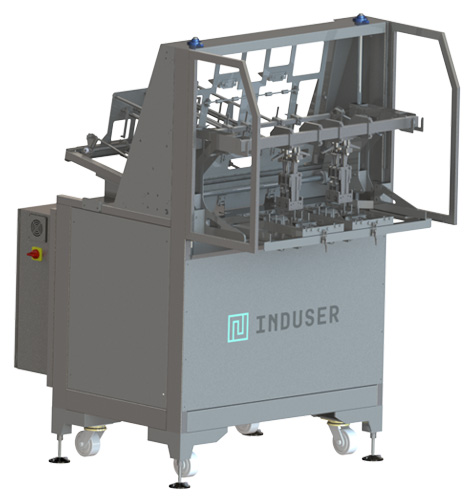

Cardboard or plastic trays, buckets, lidded cups, clamshell trays. We custom design loaders that dispense trays to align with your business commitments.

Easily integrates into our range of end-of-line machines and machines from other suppliers specializing in sorting and heat sealing.

Our machines are manufactured in stainless steel and materials with the highest performance, facilitating regular cleaning and, consequently, ensuring durability and profitability.

This machine operates using sheets or boards of cardboard, an environmentally friendly material increasingly required by regulations in various countries to reduce plastic usage.

This machine easily integrates into single and double packaging lines.

The machine's cadence adapts according to the number of heads, which can be 2 and 4.

While this machine is exclusive for the use of cardboard trays, it does support multi-format trays.

Like all INDUSER solutions, the accessories that compose this machine (heads, molds, and loaders) are custom designed.

Our machines are manufactured in stainless steel and materials with the highest performance, facilitating regular cleaning and, consequently, ensuring durability and profitability.

They include a series of accessories to dispense, fill, close and cap a variety of packaging formats.

Based on the production capacity, the chain conveyor belt can be single or double. Its functionality allows fast format change by replacing the denester for other packaging specifications.

DOWNLOAD DATASHEET

| Packaging Model |

Denests | Fills | Caps | Clips | Length adjustment |

Width adjustment |

Height adjustment |

Vibration filling system |

||

| VDD | 6000 | 120 ppm* | ||||||||

| VSD | 4400 | 60 ppm* | ||||||||

| FSD | 3500 | 50 ppm* | ||||||||

| VST | 5000 | 75 ppm* | ||||||||

| VDT | 6000 | 150 ppm* | ||||||||

|

||||||||||

Cardboard or plastic trays, buckets, lids, clamshells. We adapt the packaging machine to the variety of containers you use.

Denests, fills and packs in a fully automated manner.

They are easily integrated into our range of weighers and end-of-line machinery. This is how we adapt the entire production line.

We distribute the product efficiently to package with the specifications of the weighers.

Ensuring that the product is loaded safely and efficiently.

Our machines are made of stainless steel and materials with the highest performance. This facilitates their regular cleaning and with it, their durability and profitability.

They include a series of accessories to dispense, fill, close and cap a variety of packaging formats.

Based on the production capacity, the conveyor belt can be single or double. Its functionality allows fast format change by replacing the denester for other packaging specifications.

DOWNLOAD DATASHEET

| Packaging Model |

Denests | Fills | Caps | Clips | Production capacity |

Length adjustment |

Width adjustment |

Vibration filling system |

||

| LT | 3000 | 80 ppm* | ||||||||

| LD | 3000 | 60 ppm* | ||||||||

| LT | 4000 | 80 ppm* | ||||||||

| LD | 4000 | 60 ppm* | ||||||||

|

||||||||||

Cardboard or plastic trays, buckets, lids, clamshells. We adapt the packaging machine to the variety of containers you use.

Denests, fills and packs in a fully automated manner.

They are easily integrated into our range of weighers and end-of-line machinery. This is how we adapt the entire production line.

We distribute the product efficiently to package with the specifications of the weighers.

Ensuring that the product is downloaded safely and efficiently.

Our machines are made of stainless steel and materials with the highest performance. This facilitates their regular cleaning and with it, their durability and profitability.

It denests, fills and closes pouches by adding two security systems: zipper closure and/or heat sealing. Open pouches are suitable for this solution.

The FB30 is simply integrated into our range of circular and linear weighers.

| Packaging Model |

Films | Pre-made pouch | Denests | Fills | Wraps | Zipper | Trays with product | Large products | Small products | Bag capacity adjustment | ||

| VERTICAL FLOW PACK | ||||||||||||

| FB30 | ||||||||||||

|

||||||||||||

Denests and fills automatically.

Supports paper bags.

Ideal for bagging with zipper and heat sealing.

Ideal for protecting small products.

Parameter regulation by touch screen.

Our machines are made of stainless steel and materials with the highest performance. This facilitates their regular cleaning and with it, their durability and profitability.

An ideal solution for a wide range of small or medium-sized products.

ADVANTAGES

| Packaging Model |

Films | Pre-made pouch | Denests | Fills | Wraps | Zipper | Trays with product | Large products | Small products | Bag capacity adjustment | ||

| VERTICAL FLOW PACK | ||||||||||||

| FB30 | ||||||||||||

|

||||||||||||

Bags of different dimensions in film.

Wraps product of small and medium dimensions.

Tomatoes and peppers, apples, and stone fruits. A solution that serves more than one product.

The dimensions of the bags can be adjusted.

Parameter regulation by touch screen.

Our machines are made of stainless steel and materials with the highest performance. This facilitates their regular cleaning and with it, their durability and profitability.

A label sealing system makes the SEAL LABEL an alternative that reduces the us of plastic by 30% compared to traditional packaging formats.

For safety and protection to be possible, the machine places a transparent label, which adds ventilation to the packaged product and allows it to be reclosed once it is opened for the first time.

DOWNLOAD DATASHEET

It packs up to 100 trays per minute.

The machine admits trays with a capacity of up to 2000gr.

The Seal Label is easily integrated into our range of weighers and end-of-line machinery. Our speciality is designing customized engineering solutions.

An intuitive software allows the configuration of the different formats available. The change happens in a couple of clicks.

A machine designed for R-PET or Cartonpack® cardboard trays.

Our machines are made of stainless steel and materials with the highest performance, which facilities their regular cleaning and with it, their durability and profitability.

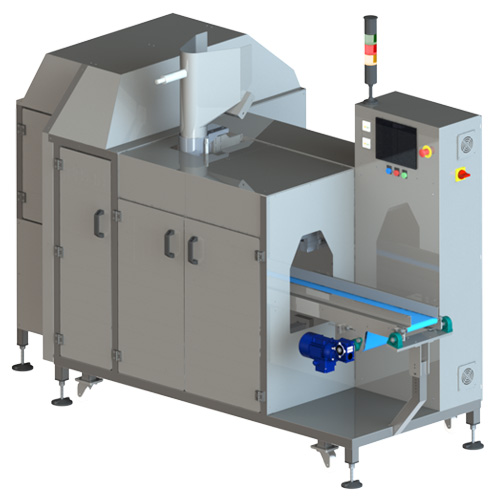

The vertical Flow pack, which traditionally uses film to bag products, adapts to cartoPaper®, a paper made from 100% recyclable and compostable materials certified by the FSC.

DOWNLOAD DATASHEET

A machine conceived for bags in cartoPaper®, a 100% recyclable material.

Bags 25-40 units per minute.

It can bag a variety of product weighing between 500- 1.5 kg.

The Paper Bagger is easily integrated into our range of weighers and end-of-line machinery. Our speciality is offering comprehensive engineering solutions.

To ensure that the bags can be held with the product at the point of sale, the vertical Flow Pack integrates a stable bottom system that is activated or deactivated from the machine’s screen, without the need to change any part manually.

Our machines are made of stainless Steel and materials with the highest performance, which facilitates their regular cleaning and with it, their durability and profitability.

We are certified by International Quality and Environment Care Organizations.